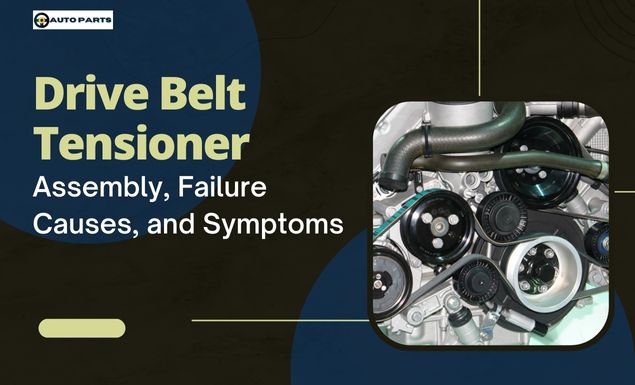

The drive belt is essential to the performance of your engine’s accessories, including the power steering pump, alternator, and compressor. The drive belt tensioner ensures that it is wound securely against each pulley.

A squeaking or grinding sound, especially while starting your engine, is one sign that your car belt tensioner may malfunction. The alternator, water pump, and AC compressor may eventually be affected by this, and your car may possibly become inoperable.

Failure of the serpentine belt tensioner will result in a broken timing belt. As a result, your engine will experience a number of problems, including poor performance.

Table of Contents

ToggleDrive Belt Tensioner Assembly

The drive belt, commonly known as the serpentine belt, and the belt tensioner work together to keep the engine’s components moving. Through a grooved rubber loop connected to pulleys, the drive belt connects several systems. The rubber loop keeps the pulleys for the water pump, alternator, air conditioning compressor, and power steering pump moving when the engine is operating. With the help of the belt tensioner, the belt transmits the power from the engine to these systems.

A pulley that is attached to a bracket specifically designed for the vehicle serves as the belt tensioner in many cases. The component tightens the pulleys so that the engine components function as desired.

The engine belt tensioner, which is traditionally spring-loaded, can enlarge or reduce in size as needed. Any belt must be under the proper pressure for your engine to function correctly.

Potential Causes of Drive Belt Tensioner Failure

The serpentine belt tensioner will eventually lose its ability to provide tension to the belt over time. Through repeated usage, a mechanism may occasionally become weakened or seized. Sometimes, a pulley may deform, crack, or lose a bearing entirely.

When this occurs, the belt has a chance to slip, which will weaken or damage it more quickly. Serpentine belt failure can seriously harm your engine if it causes it to slip off multiple pulleys.

Hydraulic fluid leak: The hydraulic tensioner unit for the timing belt functions as a shock absorber. The hydraulic fluid keeps the tension in check.

Deterioration: The belt tensioner spring on a modern mechanical belt tensioner system is coiled securely by two tension rods. The spring loses tension and expands out with time. Thus, the entire tensioner weakens.

Dust and Dirt Accumulation: The drive belt won’t be supported by the pulley in case of dirt accumulation. Consequently, it will become a loose belt tensioner.

Symptoms of a Bad Belt Tensioner

Here are a few major signs of a bad belt tensioner:

Rusting and Cracks

There could be the presence of rust between the arm and base. Check the tensioner’s arm, housing, and bracket for any damage or cracks. Rust indicates the wearing of interior components.

Wearing of Pulley Bearings

Rotate the pulley manually with the engine off and the belt off. If you experience noise, resistance, or roughness, pulley bearing wear is probably the cause of the issue. Replace the tensioner assembly as a whole in such cases

Pulley Deterioration

The surface of a pulley can be either flat or grooved. Flat and grooved surfaces should be flawless and devoid of dents, chips, and fractures. Moreover, the high points of the grooves must be uniform in height and unworn. So, if the belt tensioner pulleys are not in good shape, your car is at risk.

Misalignment of the Tensioner Assembly

Faulty tensioner installation and a bent or misaligned mounting bracket can cause the failure of the auto belt tensioner.

Belt Tensioner Noise

The driving belt begins to make noise when the connections are loose. The tensioner makes

- Rumbling sound

- Squeaking

- Knocking sound

Excessive Tensioner Arm Oscillation

Continuous oscillation is a sign of spring torque or dampening system failure. Additional probable causes of the drive belt and tensioners failure include malfunctioning of the torsional vibration absorber or overrunning the alternator pulley. The best course of action for this problem is to replace the tensioner.

Spring Force Loss

Use a wrench to rotate the tensioner arm all the way around. If this movement does not offer resistance, it indicates a weakening of the spring belt tensioner force.

When to Choose for Belt Tensioner Replacement?

It’s critical to understand when to change the belt tensioner in a car. Apart from all the above indicators, one more factor which is taken under consideration is the distance travelled by car. The need to repair the belt tensioner increases as your vehicle becomes older and travels more miles.

You should replace your belt tensioner between 50,000 and 80,000 miles. However, to avoid component failure, never try to repair a broken pulley in a used tensioner assembly. Instead, replace the complete tensioner system.

Belt Tensioner Replacement Cost

Depending on where you go for service or choose to do it yourself, replacing your car’s drive belt tensioner will generally cost between $300 and $350. This price range excludes taxes, fees, and the particular make and model of your vehicle.

If your drive belt tensioner is broken or working poorly, then the best way to solve the problem is to replace it. However, buying new components can be heavy for your pockets. An alternative method is to buy a used drive belt tensioner. At Auto vehicle parts, you will get the quality used drive belt tensioner at an affordable price.

To continue reading more hacks and blogs check below mentioned list.